Thermomoulding & Metal Injection Moulding: Understanding the differences between two key manufacturing processes

When choosing a manufacturing process, it is essential to carefully consider your specific needs. Each method has distinct advantages and disadvantages.

Vulkam’s thermomoulding process offers a unique opportunity to guarantee both high precision and the ability to adapt production to large volumes, all exclusively with amorphous metal alloys.

Metal injection moulding (MIM) is a good option for small, uncomplicated parts produced in large series.

Metal Injection Molding

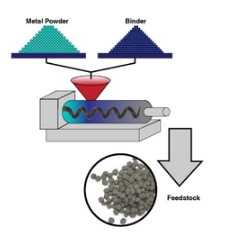

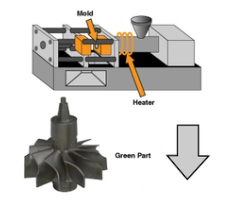

MIM is a forming process based on plastic injection and powder metallurgy.

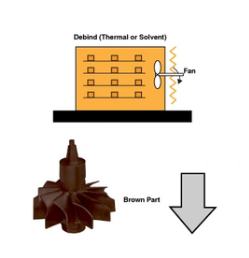

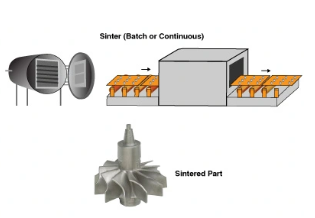

The MIM (Metal Injection Moulding) process consists of four main successive stages, each of which plays an essential role in transforming metal powder into a functional part.

The four steps of injection moulding:

Results

At the end of the MIM process, the result is a metal part:

- With complex geometry

- Produced in large series

- With good repeatability.

- Average geometric precision (in any case significantly lower than machining)

- Average surface finish, with roughness similar to that of the metal powder used.

Vulkam's thermomoulding process: an alternative to MIM

The thermomoulding process developed by Vulkam is one of the world’s most advanced innovations for shaping amorphous metal alloys: Vulkalloys®.

This patented technology, developed entirely in-house, was designed to meet the production needs of small parts ranging from a few tenths of a millimetre to a few centimetres in size.

Step 1 : alloy production

In a specialised machine, alloys containing zirconium, nickel and copper are mixed and homogenised in liquid form. The specific nature of this alloy production process means that it does not tolerate contamination and is therefore carried out:

- at high temperatures

- in a perfectly clean gaseous environment,

- under perfectly controlled crucible melting conditions to avoid contamination.

This production method allows large quantities of Vulkalloys® to be manufactured while guaranteeing:

- Perfectly controlled chemical composition

- Impeccable material quality

The solidified material in the form of small, calibrated pieces constitutes the primary alloy intended for shaping. This step also allows 100% of the molten material to be used, thereby saving resources in an increasingly constrained world.

Step 2 : Thermomoulding

These pieces are then processed in a second machine.

During this stage:

- the pieces are melted

- and then injected vertically into a metal mould, using a process developed by Vulkam.

This is where the transformation into amorphous material takes place: the liquid metal is cooled quickly enough that the atoms do not have time to organise themselves into a crystalline structure.

This absence of crystallisation, resulting in a disorganised structure at the atomic level, is the signature of amorphous materials and leads to exceptional properties:

- High hardness and strength, superior to those of conventional metallurgy.

- Excellent elasticity, ideal for deformation parts (springs, flexible blades).

- High resistance to corrosion and wear.

A distinctive technology, unique in the world

This high-precision thermomoulding process, which is unrivalled worldwide, offers several major advantages:

Production of small parts and miniature components with optimised geometries.

Complete control of the alloy and the process, from melting to forming.

Material savings thanks to direct injection of molten material

In summary, MIM is a proven and cost-effective solution for the mass production of small metal parts.

Vulkam thermoforming offers a major technological advance, enabling the manufacture of micro-parts in amorphous alloys with unrivalled precision, quality and performance.

Thermomoulding process vs Metal Injection Moulding

Criteria

Thermomoulding

Metal Injection Molding

Material

Amorphous metal alloys (Vulkalloys®)

Metal powder & binders

Porosity

No porosity

Residual porosity possible

Precision

High precision, no shrinkage

Good but affected by sintering srinkage

Size of parts that can be produced

Small parts (mm to a few centimetres)

Small parts (mm to a few centimetres)

Part complexity

Complexity

Very high complexity

Process duration

Direct process

3-step process

Surface finition

Excellent (Ra=0.4µm)

Average( 0.8µm ≤ Ra≤ 1.6µm)

FAQ

Their non-crystalline atomic structure gives them superior hardness, elasticity and fatigue resistance.

No. MIM is based on powder metallurgy. Amorphisation requires ultra-rapid cooling, which is impossible to achieve using this process.

No, amorphous transformation imposes a size limit (a few centimetres maximum).

No. These are two different processes, each suited to different needs.