[German ![]() version available here]

version available here]

Vulkam, an innovative microtechnology SME based in Grenoble, has developed a range of innovative metals (amorphous metal alloys) particularly suited to the medical industry. These metals enable the production of micromechanical parts with unparalleled properties, by means of a specific process allowing the miniaturisation of instruments.

Context and challenges in the design of microsurgical instruments

The design of microsurgical and endoscopic instruments is currently confronted with a limit to the characteristics of the materials and the proposed implementation solutions.

In order to innovate in this field, DM manufacturers aim to

- improving the ergonomics and performance of the instruments,

- greater precision of the surgical gesture,

- less invasiveness,

- greater durability of instruments.

A more precise procedure

The Vulkalloy® Zr-Med family of amorphous zirconium-based alloys has been specifically developed for the medical field and more particularly for instrumentation.

It has very high mechanical properties and is twice as strong as the reference medical alloy (TA6V). This allows the production of parts up to two times smaller, miniaturising instruments and opening the way to more precise and less invasive surgery.

A unique manufacturing process

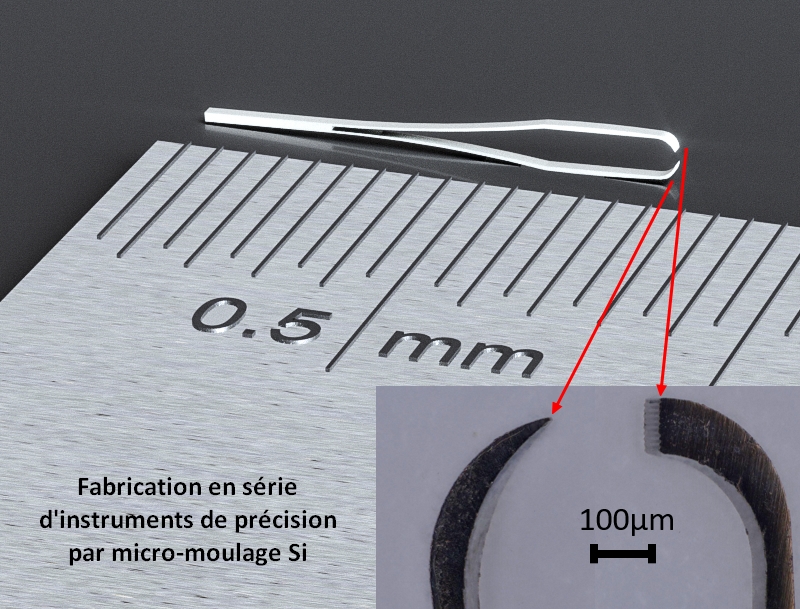

The exceptional properties of the material can be coupled with the proprietary Silicon thermo-moulding process, which allows the mass production of millimetre to micrometre-sized parts with very high precision and the possibility of adding very small functional areas without additional cost.

Indeed, once the alloy (raw material) has been developed, thermo-moulding injection allows the final shape of, for example, clip tips to be obtained to the desired dimensions, with micrometre tolerances and mirror surface finishes if required.

Current processes for producing miniature components often include expensive technologies with a large number of steps such as sheet metal processing, cutting, bending, machining, shaping, grinding, reworking, polishing, often manually, as well as heat or surface treatments. This simplifies and accelerates production and reduces costs, particularly by limiting the time-consuming and costly steps required to finish the components.

Thus, the use of Vulkalloy® Zr-Med by this process offers a real technological and economic breakthrough for the production of miniature components constituting microsurgical instruments.

Biocompatible

Parts made of Vulkalloy® Zr-Med are free of CMR or allergenic compounds (such as Ni or Co). In support of ISO 10993-1, VULKAM has subcontracted cytotoxicity and salts analysis tests to accredited laboratories (tests based on standards 10993-5 and 10993-18). The results are consistent, including post-cleaning and sterilisation.

A variety of applications

Vulkalloy® Zr-Med is used in many fields of application: medical devices for minimally invasive surgery and dentistry, high-precision instruments: forceps, biopsy, suture, endoscopy, endodontics, orthodontics, optics, micromotors, etc.

www.vulkam.com

Industrial Silicon thermo-micro-moulding process