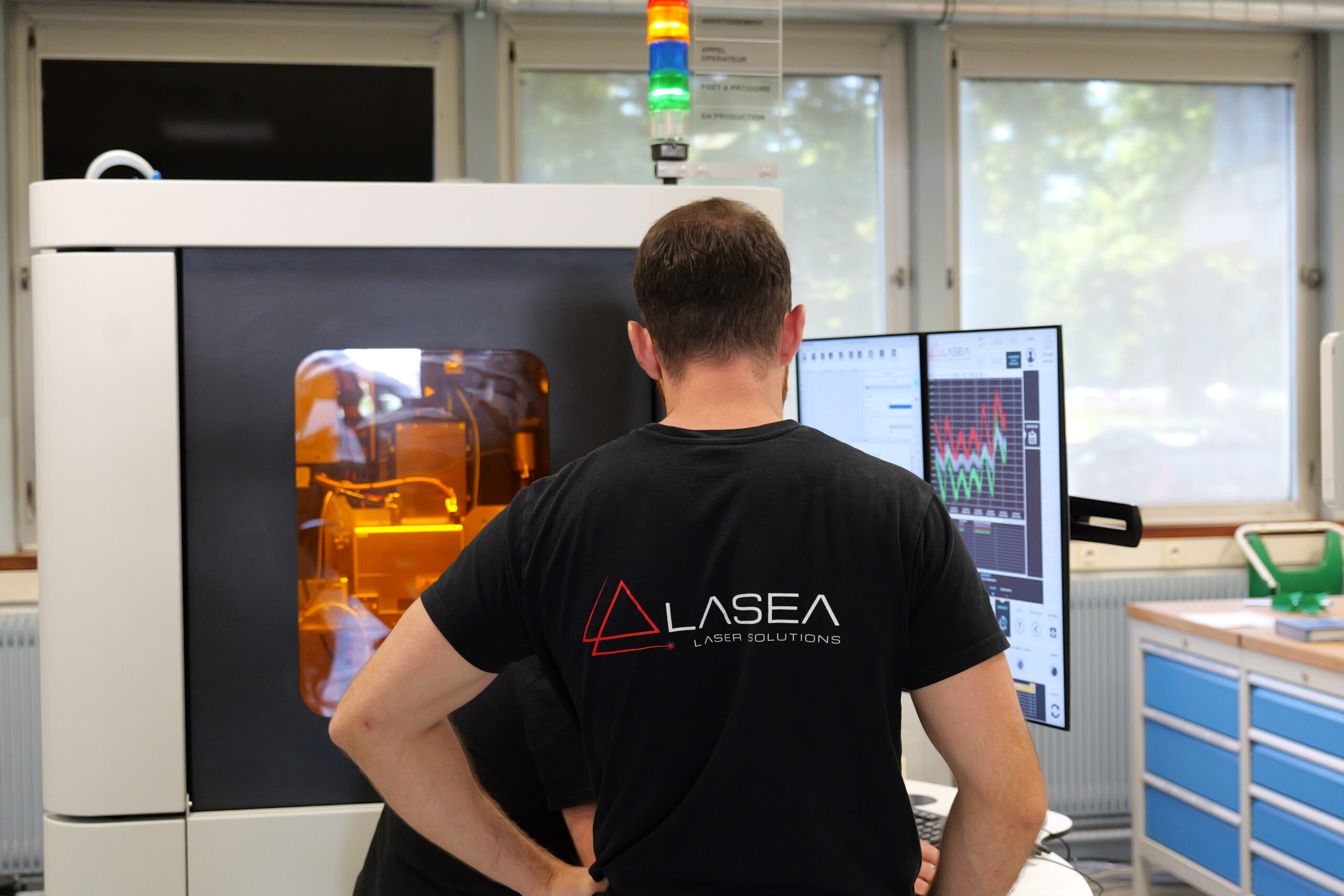

LASEA x VULKAM webinar: Can lasers reinvent watch production?

Vulkam recently participated in a webinar organized by LASEA, whom we thank for their invitation, dedicated to the use of lasers in the manufacture of high-precision watch components.

Through this webinar, discover the unique potential of combining laser technology and amorphous metal alloys for the manufacture of high-precision watch components.

Vulkalloys® coupled with laser technology

Through concrete examples, Vulkam shared its experience with combining laser technology and Vulkalloys® amorphous metal alloys, which are particularly well suited to laser cutting.

Vulkalloys® differ from conventional alloys in their amorphous atomic structure, which gives them specific mechanical and physical properties: high hardness, excellent corrosion resistance, low friction coefficient, non-magnetic properties, and exceptional surface quality. These characteristics make them particularly suitable for high-precision laser cutting operations.

The applications presented cover both watch parts and movement components, with measurable gains in terms of reduced wear, functional stability, and durability.

Vulkam also detailed its progressive industrialization approach:

- Vulkalloys® preforms for rapid testing, qualification and prototyping without specific tools.

- Thermoforming for medium and large-scale ramp-up, with competitive per-part costs.

The LASEA & Vulkam partnership demonstrates the complete technological compatibility between Vulkalloys® and laser technology, paving the way for more integrated, reliable manufacturing processes without compromising on precision.

Vulkalloys® watch movement

Vulkalloys® & Laser cutting: an optimized manufacturing line for watchmaking micromechanics

The partnership between Vulkam and LASEA is based on an integrated manufacturing chain, specifically optimized for Vulkalloys® amorphous metal alloys and the requirements of watchmaking micromechanics.

1. Selection of the Vulkalloys® preform

The process begins with the selection of a standard Vulkalloys® preform (ring or washer), chosen according to the final geometry and functional constraints of the part. This step allows us to start with an already optimized material, limiting material losses and intermediate operations.

2. Thinning of the preform

The preform is then thinned to achieve the target thickness with excellent surface homogeneity. This operation ensures optimal preparation before final shaping.

3. High-precision laser machining

The geometry is achieved by femtosecond laser cutting, resulting in a final part with an accuracy of ±2 µm.

4. Obtaining the final part

The part is delivered with its intrinsic properties intact: high hardness, non-magnetic, low friction, excellent surface quality, and corrosion resistance.

Thanks to the compatibility between Vulkalloys® and LASEA laser technology, this manufacturing chain reduces the number of steps, repositioning, and risks, while pushing the boundaries of micromechanics in watchmaking.

Webinar replay