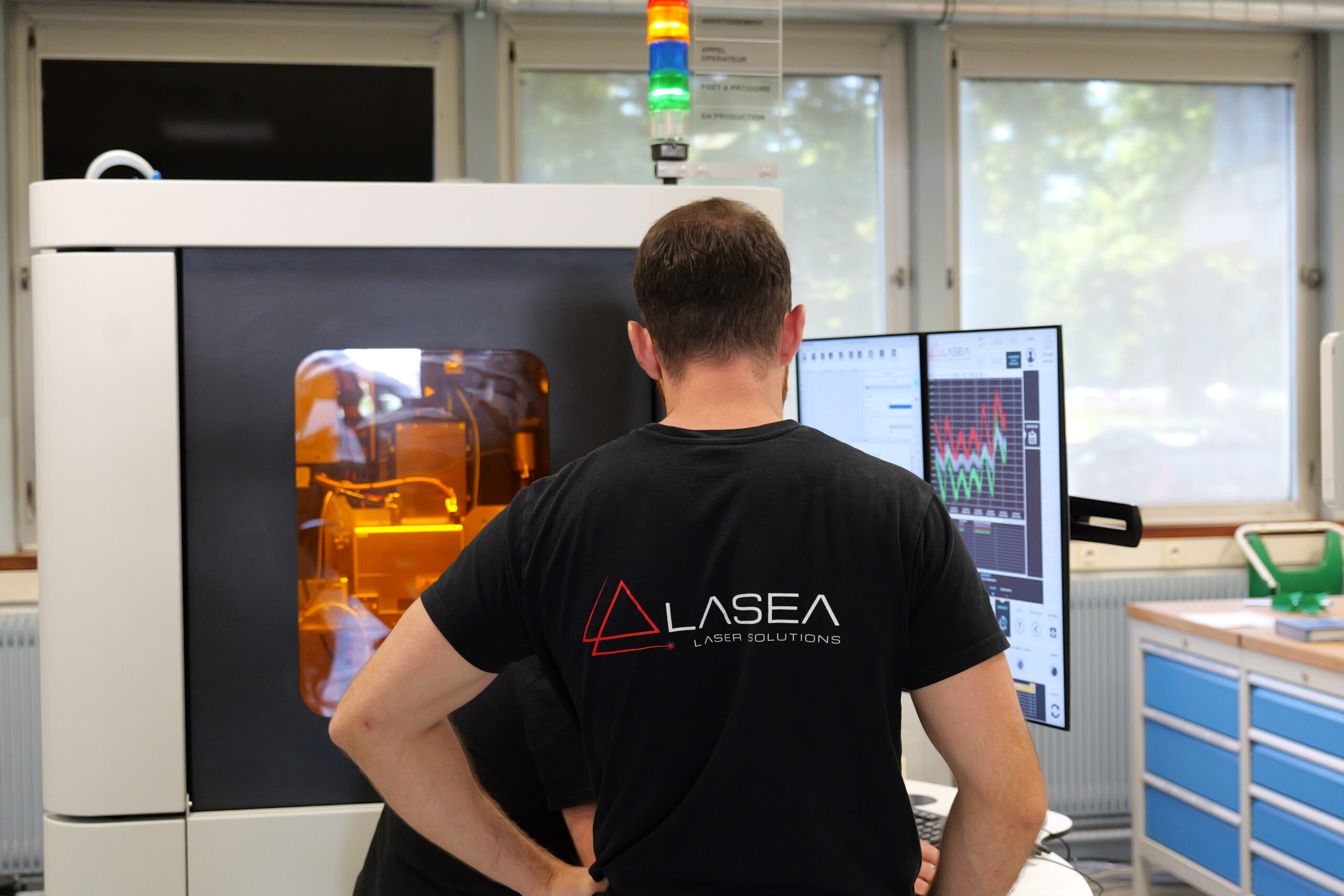

The Femto Laser LS4-P from Vulkam and Lasea highlights the unique compatibility of Vulkalloys® amorphous metal alloys with Femto technology.

At Vulkam, each Vulkalloy component is the result of a unique process designed to meet the requirements of watchmaking.

Starting with a ring preform, we control every step, from thickness control to laser cutting, to guarantee parts of impeccable precision and quality.

Why are Vulkalloys® amorphous metal alloys ideal for laser cutting?

Our developments show that Vulkalloys® are the most suitable metal alloys for laser cutting, offering unrivalled precision and reliability for micromechanics, thanks to complete control of each stage, starting with a ring preform.

Our customers therefore benefit from the possibility of obtaining their parts quickly, with the guarantee of dedicated support if they wish to increase production rates.

Vulkam’s LS4-P Femto Laser is the result of a collaborative project with LASEA, initially dedicated to studying the use of femtosecond lasers on amorphous metal alloys.

Today, this partnership is opening up new possibilities: the perfect compatibility between Vulkalloys® and LASEA technology is pushing the limits of micromechanics in the watch industry.

An uncompromising manufacturing process

Thanks to this innovation, we offer a manufacturing process tailored to the exceptional metallurgical quality of Vulkalloys® with few constraints on design and machining.

Extremely accurate cutting and engraving (up to ±2 µm)

No deformation of the material

A perfect finished edge for straight sides

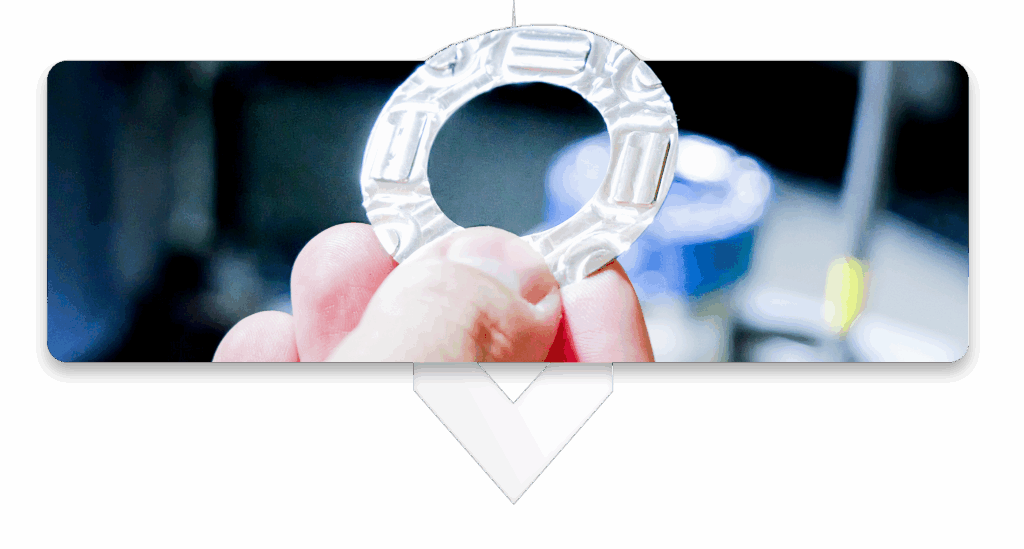

Choice of preform

rom our catalog of standardized preforms, you choose the Vulkalloys® preform best suited to your component.

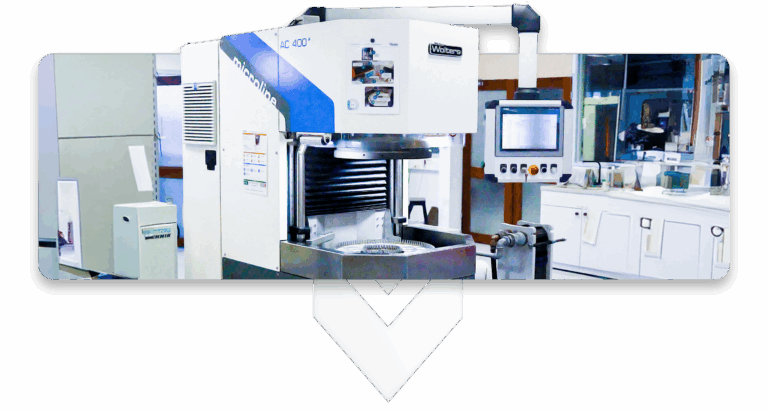

Thinning

We then proceed to a thinning stage to achieve the ideal thickness and prepare the surface. This process is suitable for any part with a minimum thickness of 120 µm.

Laser processing

Finally, we perform Femto laser LS4-P cutting to obtain the final part with an accuracy of ±2 µm.

Final piece

Obtain a final part made of amorphous metal alloys with exceptional properties.

The exceptional properties of Vulkalloys® metal alloys

Take advantage of Vulkam’s expertise and innovative alloys to meet your industrial challenges and open up a whole new range of possibilities for your products.

- 3X stronger than steel

- High elasticity

- Non-magnetic

- High hardness and endurance