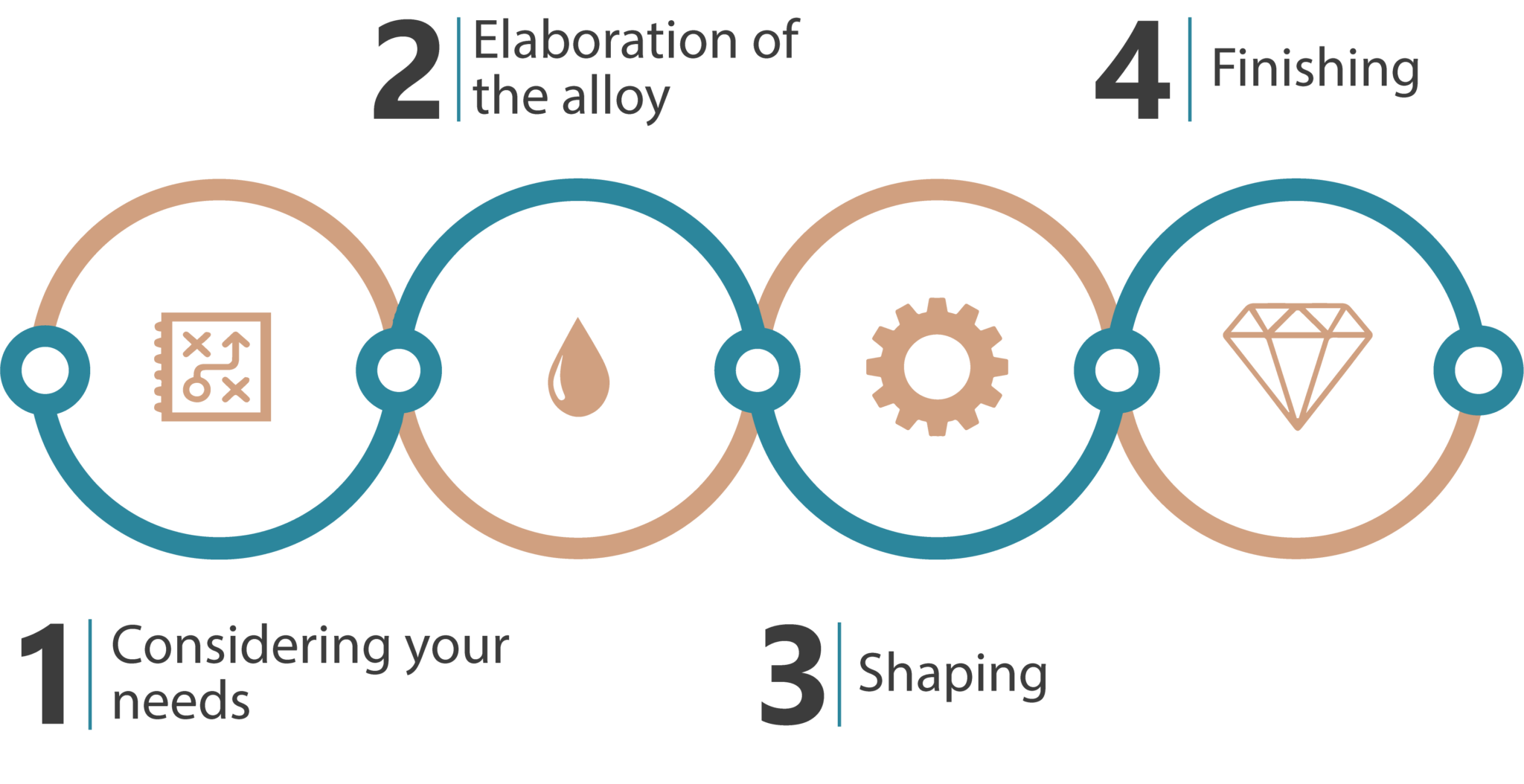

On the way to industrial production

Our progress in 2024 for your success in 2025 Les évènements de l’année 2024 EPHJ,

Our range of metals with unchallenged properties will set a future standard in metallurgy and metal processing

Watchmaking, Luxury, Medical, Aeronautics, Space, Defense: By providing stronger, more precise and smaller parts to the micromechanical industries, Vulkam is already offering innovative solutions to manufacturers.

Specifically designed for these breakthrough materials, Vulkam’s manufacturing processes are patented, and adapted to the production of miniature parts (a few tenths of a millimeter to a few centimeters)

Our progress in 2024 for your success in 2025 Les évènements de l’année 2024 EPHJ,

A revolution in surgery : Breaking the boundaries of traditional materials with Vulkalloys Current limitations

Vulkam bei der Begegnung von Innovation und Präzision auf den Herbstmessen 2024 Wir freuen uns,

1025, rue de la Piscine

38610 Gieres